After the catastrophic failure that occurred in a high-pressure Screw Plug enclosure in Japan and subsequent failures that were witnessed time and again in several parts of the world, this design screw plug lost its significance to a large extent.

TEMA INDIA decided to conduct an extensive research program to bring about key changes to make this screw plug heat exchanger design totally safe and free of maintenance problems.

FEA analysis carried out at TEMA INDIA

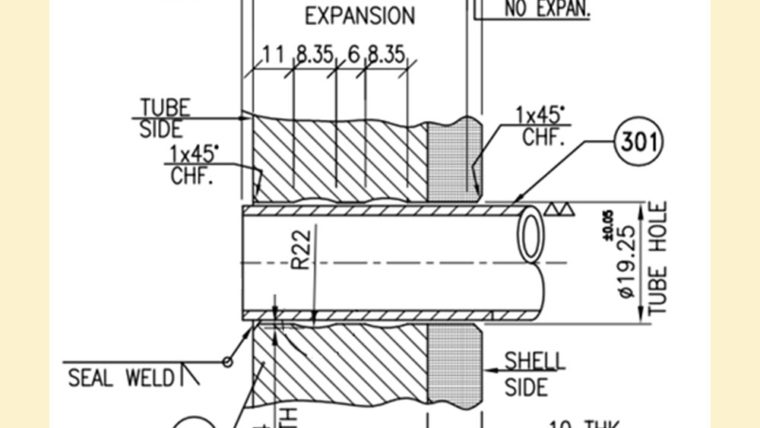

TEMA INDIA had to carry out an extensive structural analysis to arrive at a need for Added Steel on the threaded portion of the enclosure. FEA analysis carried out at TEMA INDIA on the standard units revealed that due to the uneven thermal expansions, undue/unaccounted stresses are developed. This resulted in bell mouthing in the threaded region thereby reducing the shear area of the threads, i.e. some part of the threads would not be full engaged. This further resulted in expelling of the plug in an extreme circumstance, causing an explosion or jamming of the threads (as was often experienced).

TEMA INDIA LTD. conducted several experiments and performed destructive testing on prototype to ensure that the added steel in fact restricted any such distortion and resulted in easy removal of the plug.

It can be seen by analysis that the magnitude of bending stress can amount to three times the average longitudinal stress in the undercut area. This phenomenon can be logically understood and supported by calculations to show that the combined bending and longitudinal stresses on the undercut surface of the threads produce a wedging action that results in radial displacement, causing dilation of the channel. Therefore this dilation, that is a cause of reduction in shear area, has to be restricted by using higher wall thickness in the threaded region. This higher wall thickness of the channel barrel immensely shoots up the cost of the forging.

TEMA INDIA Installed 151 Screw Plug Heat ExchangersTEMA INDIA has therefore adopted its own technology of added steel to overcome this phenomenon of bell mouthing and has been awarded an Indian Patent for the same. TEMA INDIA has manufactured and installed 151 screw plug heat exchangers in high pressure, high temperature and corrosive nature of fluid conditions, in many hydrocrackers, hydrotreaters and ammonia synthesis process, in Oil & Gas and Fertilizer sectors and several more are in manufacturing stage.