In this article an attempt has been made to quantify the quality built into a shell-and-tube heat exchanger by an experienced manufacturer.

A shell-and-tube heat exchanger is the only equipment in a process plant that has two different fluid streams at different temperatures and pressures flowing through two distinct chambers, which are mechanically sealed from each other. Due to its complex construction and demanding operating conditions, failures are not uncommon. Furthermore, heat exchangers are deployed for dirty service and need to be dismantled for servicing, rendering gasket joints susceptible to leakage. Internal and external leakages have a bearing on safety, resultant losses and the quality of the end-product due to intermixing of two fluids.

All heat exchangers are ordered and manufactured in compliance with international construction codes and project specifications. All the same, plant operating companies experience a marked difference in the performance, ease-of-maintenance and effective life of equipment supplied by different manufacturers around the globe. This indicates that there are some finer aspects in heat exchanger design and manufacturing that are beyond the scope of codes and specifications. Therefore, compliance with specifications alone cannot be the measure of equipment quality.

Quality can be defined as the value added to a piece of equipment during its conceptualisation, design & engineering, fabrication sequence and workmanship.

The added value is the cost saved during the life of the equipment (such as cost of underperformance, unplanned shutdowns, loss of production, consumables during regular maintenance and replacement of equipment before the end of its shelf life), when compared with this cost for similar equipment made by another manufacturer. The value we add far exceeds the contract price. This value addition must be considered when selecting a vendor.

We add value right from analysing the licensor’s specifications along with those of the client and the ASME code. This is done since some specifications are generic and carry requirements that may not be suited/applicable to a particular design. Also, when the requirements of multiple specifications are combined, the resulting interpretation does not always benefit the equipment. We do this at our cost to ensure satisfying results.

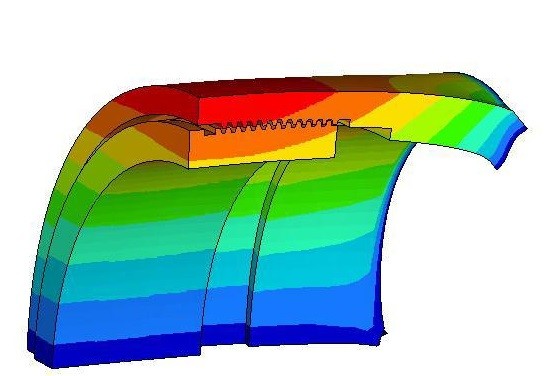

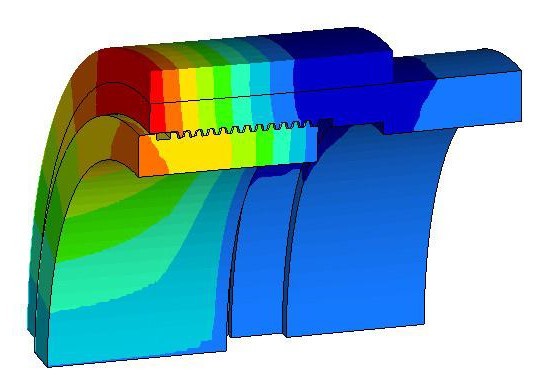

The most common problem in all types of shell-and-tube exchangers is the failure of the tube bundle itself – the heart of the exchanger and its most fragile and expensive part. Here, the failures are due to vibration and the tube-to-tube sheet joints. The former is on account of the inaccuracy of baffle holes/alignment of the baffle cage and the latter due to inaccuracies in tube sheet hole and tube expansion.

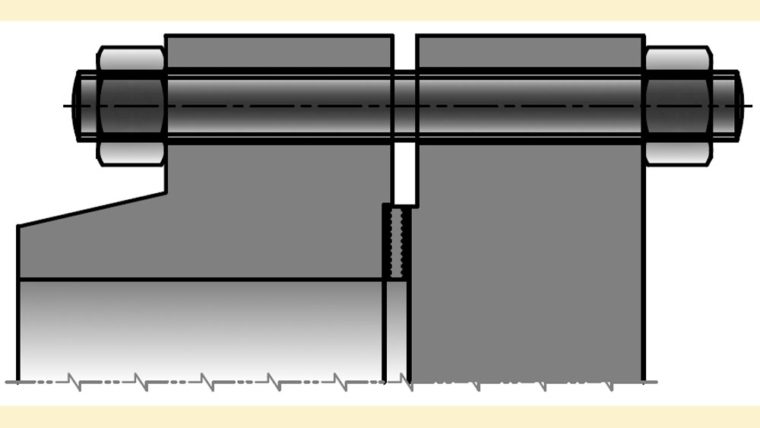

In proprietary Hi-Hi Screw-Plugs (Breach-Lock), the two most common problems are:

1. Jamming of the plug: the exchanger cannot be serviced because the plug cannot be unscrewed

2. Internal leaks in the gasket joint, resulting in a mix-up of sulphur-dirty and sulphur-clean fluids between the shell side and the tube side

Other proprietary exchangers such as Rod-Baffle exchangers and Helix exchangers pose hurdles of a similar nature.

Quantification of quality depends on the type and nature of failure of the equipment. Failure from leakage of non-toxic substances can result in shutdowns, while leakage of toxic substances can cause environmental damage or have catastrophic effects.

Copyright © 2020 Haresh Sippy

(This article is subject to copyright.)